Powered by new advanced algorithms that deliver outstanding control and a connected solution

The health of your grocery business depends in large part on the health of your refrigerated products. That’s why Copeland made it a priority to re-think case control from the ground up, creating a unit engineered specifically for today’s electronic valve equipment.

Refrigeration Controls Just Got a Whole Lot Smarter

The Copeland CC200 controller is specifically designed to handle the unique challenges of today’s retail grocery refrigeration environments. This microprocessor-based controller is designed for use in controlling temperature, superheat and evaporator pressure for refrigerated cases and walk-in boxes.

CC200 Case Controller: Simple. Reliable. Flexible. Smart.

A refrigeration control that puts you in control delivering improvements in energy savings, reliability, food quality and overall store health.

CO₂ System Refrigeration Controls

The CC200 is a premium connected controller designed to provide robust case control and communicate with the E3 supervisory control for CO₂ applications. As part of a connected infrastructure, it helps to bring a facility’s network of refrigerated cases into one view for simplified management.

Copeland has the expertise and services to help you maximize the performance and efficiency of your CO₂ system.

Case Study

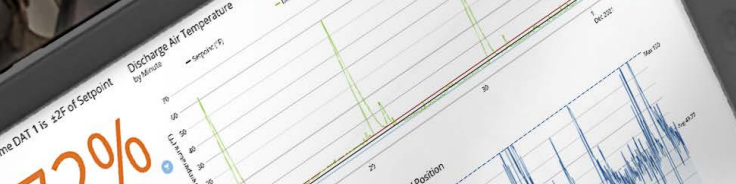

In late 2021 and early 2022, Copeland began several pilot tests of its Case Controller 200 (CC200), a stand-alone case control system, at retail stores in Dallas, Texas; Tulsa, Okla.; and Conyers, Ga. The dramatic results of these upgrades hold the promise of significant improvements in energy savings, store health scores, refrigeration system reliability and food quality. The CC200 quickly provided benefits across the board simply by replacing the existing controller. Pilot sites saw measurable improvements in system reliability and energy savings within hours, with no new sensor or valve hardware. Food quality and health scores are also on course to improve — all while simplifying service, maintenance and troubleshooting.

“The CC200 has been a good controller to work with. Wiring and programming is user-friendly. The app is intuitive and very easy to work with. It has all pertinent information in an easy-to-use format.”

Senior Project Manager

Support from Start to Finish

Get the most from your HVAC/R controls before, during and after installation with Copeland Professional Services. You’ll simplify processes, reduce frustrations and improve results.