Custom Electronic Controls from Concept through Production

For over 30 years, Copeland custom controls have provided customers with a single source of control technologies that meet the changing needs of Foodservice, Retail, HVACR and other industries. Our comprehensive application knowledge and industry expertise combine to offer a complete design and manufacturing solution of custom electronic controls. While our controls are often out of sight, they are at the heart of restaurants, convenience stores, grocery retail and other businesses where sophisticated and simple-to-use equipment is required for always-on, 24-hour environments.

Dedicated Service that Builds Long-Lasting Relationships

At Copeland, we’ll help you choose, implement and optimize the right solution for your unique application. Our disciplined team approach and tightly managed project management protocol allows us to outpace the competition in product development cycle time with uncompromising quality. Our dedicated engineering department will support and enhance your custom control over the life of the product. We become an extension of your design team and develop long lasting relationships that result in success, project after project.

The Copeland Difference

- ADVANCED MANUFACTURING

- CUSTOMER-CENTRIC DESIGN

- 100% PRODUCT TESTING

- GLOBAL COLLABORATION

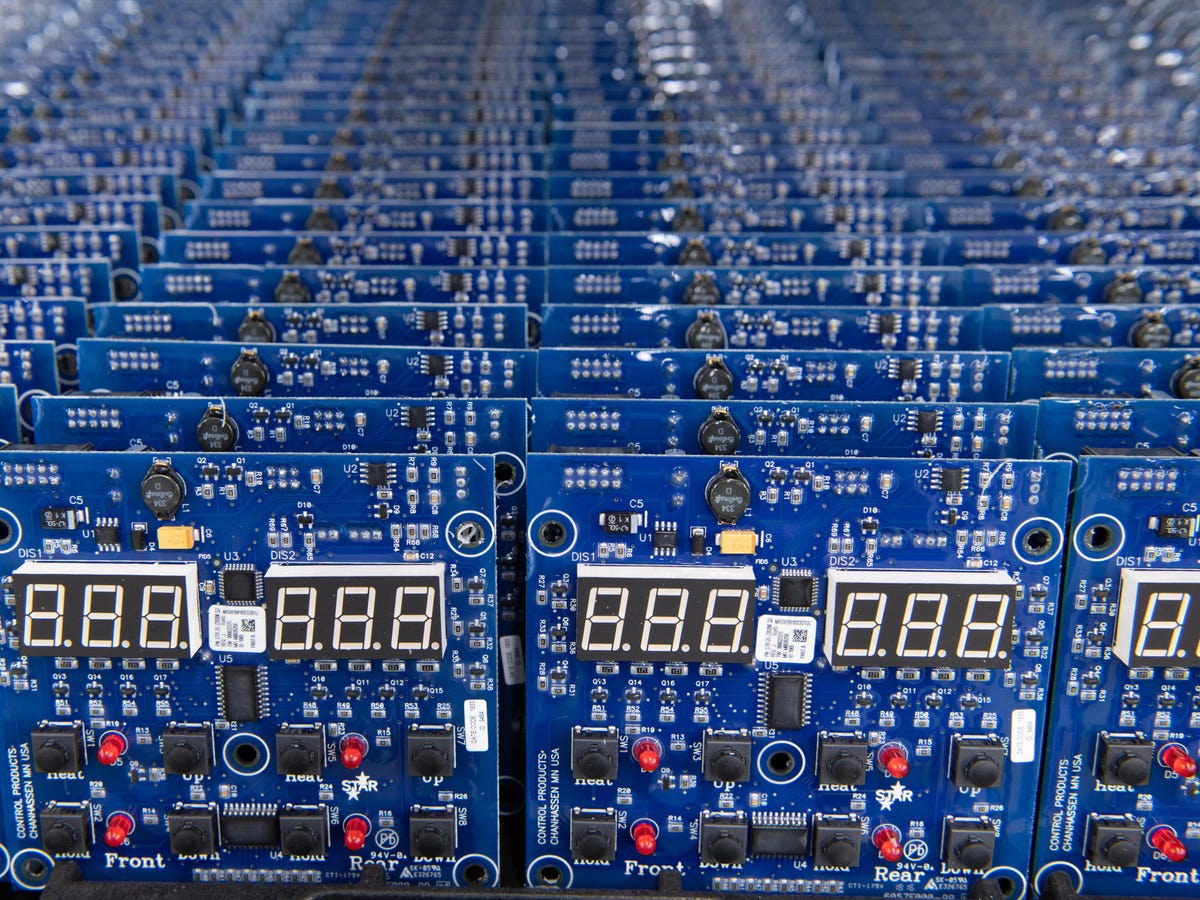

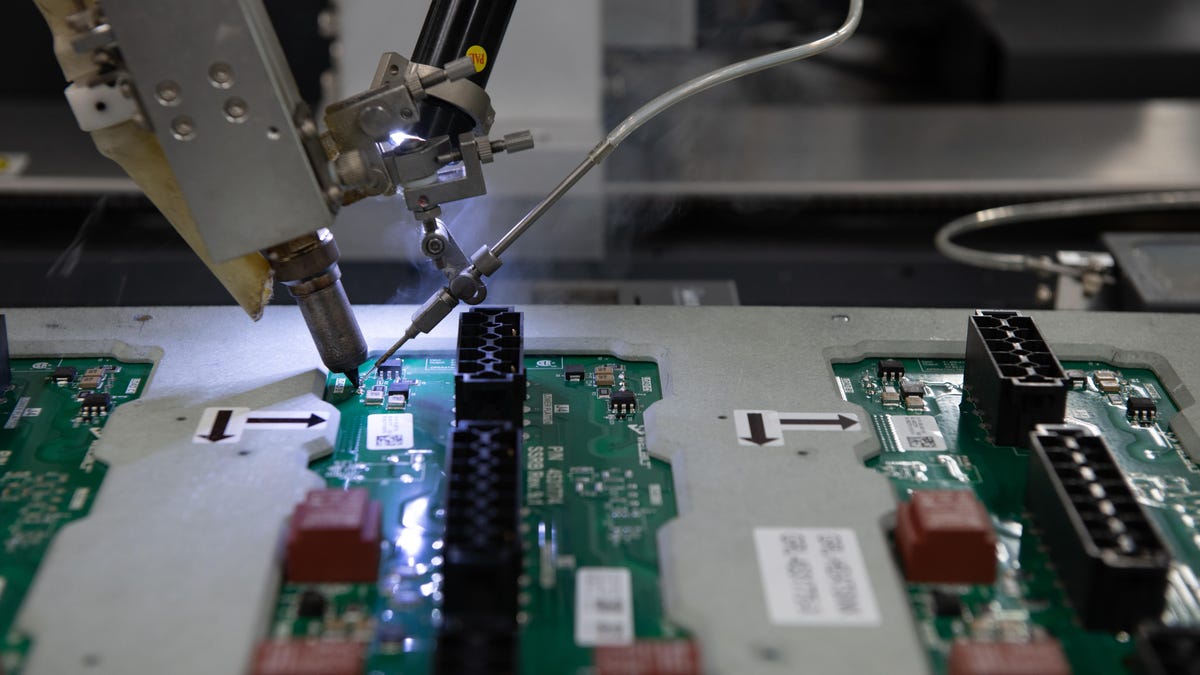

Best-in-Class Processes and Quality

Our manufacturing facilities are ISO 9001:2008 certified and offer unique capabilities to meet your specific needs. We provide expertise in both state-of-the-art surface mount and automated through-hole production, leading the way in automated production since 1985. Our services include design, component procurement, bar coding, potting, automated conformal coating, mechanical assembly, and temperature/humidity testing.

Customer Understanding and Engagement

At Copeland, we make custom controls innovation possible with a simple approach: we listen and collaborate to address your most challenging applications. You’ll find our engineers and business leaders engaged with customers across the globe – working in kitchens, exploring rooftops systems, riding with service providers and walking all types of productions processes. This real-world experience and understanding spark our collaborative problem-solving.

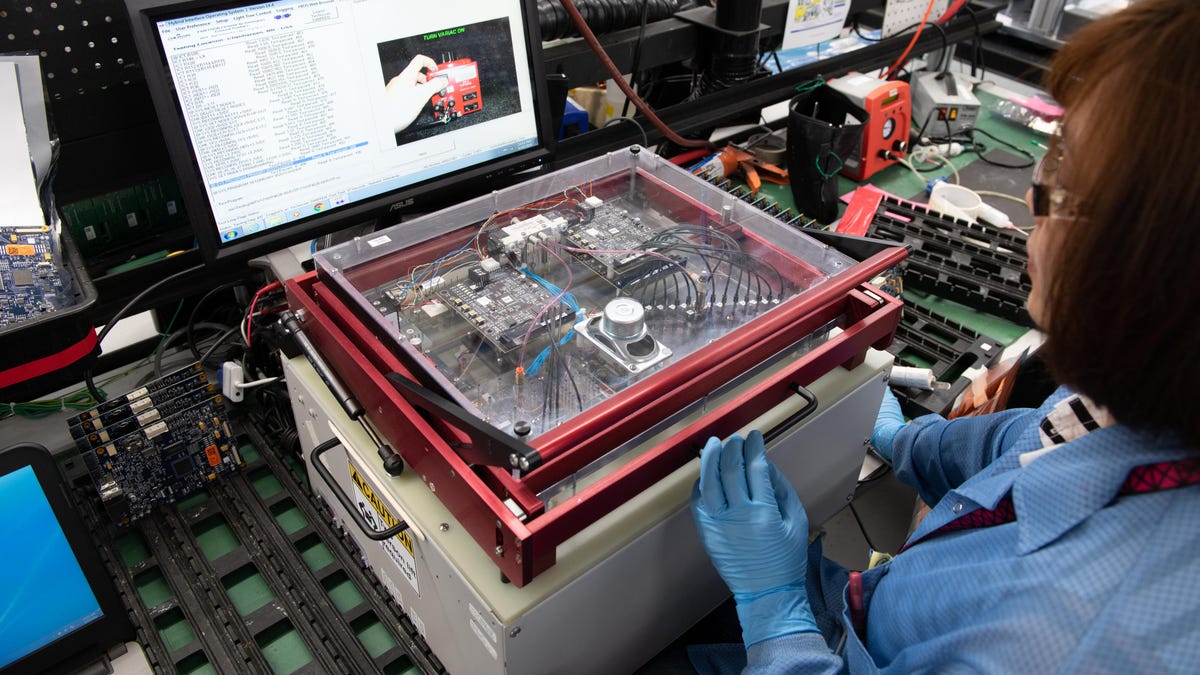

Quality Assurance

100 percent of our products are tested in the production process, using sophisticated test fixtures that combine component level verification with computerized functional operation testing. These test fixtures are tailored to each customer’s unique design to maximize coverage. Reduction in fallout and rework result in lower cost and higher efficiencies for our customers.

Worldwide Partnerships

Our global electronic component engineering and sourcing capabilities allow us to search the world to source high-quality suppliers and qualify their very best components. By combining North American and Asian manufacturing across multiple plants, our global customers benefit from world-class quality at a competitive cost.