As federal- and state-sponsored legislation incentivizes heat pump adoption in the Americas, Copeland is leading the development of energy-efficient compression and heat pump technologies.

Overcoming cold climate comfort limitations

Air-source heat pumps (ASHPs) are commonly used in ducted residential applications and packaged rooftop units (RTUs) for commercial buildings. One barrier to ASHP adoption is their inability to maintain sufficient comfort heating levels in cold climates. The Department of Energy (DOE) and the Environmental Protection Agency (EPA) have issued calls for OEMs to improve heat pump capacity and overcome these limitations. Copeland is innovating advanced compression, inverter and controls technologies that support standard, dual-fuel and RTU heat pump designs. We're working with leading residential and commercial OEMs to meet the DOE standards and accelerate their paths to commercialization.

Decarbonizing water heating

Air-to-water heat pumps are essential for decarbonizing traditional fossil fuel-burning boilers used in residential, commercial and industrial applications. Hydronic heat pump solutions provide efficient, reliable space heating by distributing hot water through pipes connected to radiant floor heating systems, baseboards or fan coil units. Industrial heat pumps offer a potential replacement of gas-powered boilers used in industrial processes and sanitation — providing hot air, water or steam — and district heating applications. Federal and state regulations and incentives — combined with corporate sustainability initiatives — are driving the decarbonization of water heating. Copeland compression and heating technologies are enabling the wider adoption of hydronic heat pumps, heat pump water heaters, and industrial heat pumps. These solutions leave a smaller carbon footprint than traditional fossil fuel-burning boilers.

Advances in compression technology are fueling the growth of current and next-generation heat pump solutions, necessary for achieving efficiency targets while meeting increased capacity demands.

Residential & Commercial heat pump compression solutions

- YAK1 AND YPK1

- YAS AND YPS

- YAV

- YHV

- YAW

YAK1 and YPK1 fixed-speed scroll compressors

- Used in many standard residential heat pumps

- Built upon the legendary ZPK7 fixed-speed platform

- YAK1 R-454B and R-32 refrigerants

YAS and YPS two-stage scroll compressors

- Used in standard and dual-fuel heat pumps

- Mechanical modulation: 67 percent for low-load conditions and 100 percent for peak-load conditions

- R-454B and R-32 refrigerants

Copeland YAV variable-speed scroll compressor

- Extends heat pump efficiency and capacity ranges

- Matches lower (part-load) and higher (full-load) requirements to optimize efficiency and capacity

- Enhanced comfort in cold climates; increased seasonal efficiencies

- R-454B refrigerant

Copeland YHV variable-speed scroll compressor

- Used in water heating: hydronic, boiler retrofits and sustainable chillers

- R-454C (A2L) enables optimized operating water-heating envelope

- Achieves required leaving temperatures in low ambient conditions

- R-454C refrigerant

Copeland YAW variable-speed scroll with enhanced vapor injection (EVI)

- Delivers maximum heat pump capacity and efficiency

- Available in small (2-, 3-, 4- and 5-ton) and large (10-, 15-, 20- and 25-ton)tonnage ranges for wide applicability in residential and commercial applications

- Enables space and water heating in low-ambient conditions

- R-454B refrigerant

Industrial heat pump technologies products

- VQ95

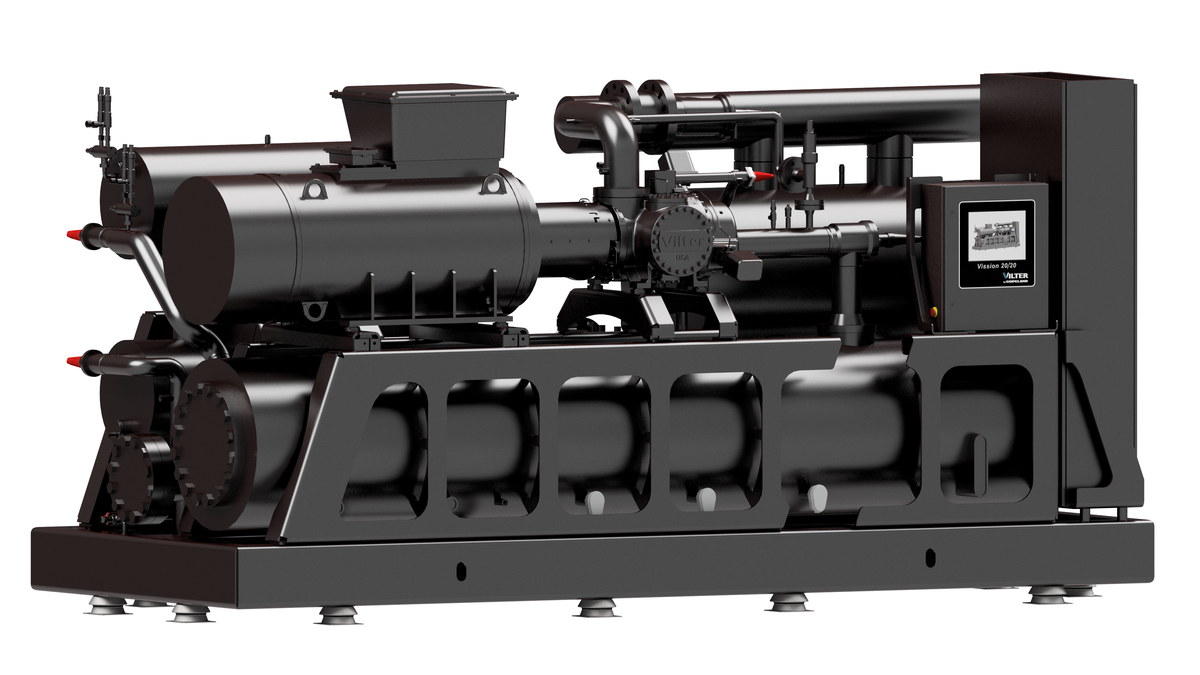

Vilter VQ95 single stage heat pump

- Designed to decarbonize industrial space and water heating

- Leverages Vilter single-screw compression technology enable unprecedented simplicity, reliability and flexibility

- 1–5 MW heating capacity per skid; modularity enables systems to be scaled with parallel or serial pipe connections

- Provides high standard temperature rating up to 95 °C with high lift capability in a single-stage system

From fixed speed, two-stage, variable-speed and vapor-injection, Copeland compression technologies are enabling wider heat pump adoption by addressing a full spectrum of application requirements.